In the world of textile weaving, shed formation plays a vital role in determining the fabric’s structure, quality, and design versatility. At GAJERA IMPEX, we use advanced shed formation technologies across our weaving machines to ensure consistency, efficiency, and the ability to produce a wide range of high-performance fabrics.

But what exactly is shed formation? Why is it so important in the weaving process? And how do different mechanisms like shaft, cam, dobby, servo drive, and Jacquard systems affect fabric output? Let’s explore in detail.

What is Shed Formation?

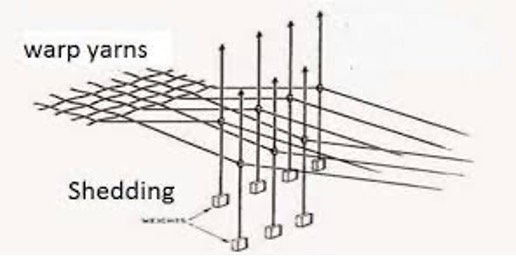

Shed formation is the process of raising and lowering specific warp threads to create a space — known as the “shed” — through which the weft thread passes during weaving. This controlled separation of warp threads is essential to form the desired interlacing of threads, ultimately creating the fabric structure.

Every time the warp threads are lifted in a specific sequence, a new pattern or weave is created. This makes shed formation not only essential for basic weaving but also a major contributor to the complexity and beauty of weave designs/fabric designs.

How Shed Formation Works in Weaving Machines?

Shed formation happens on a loom through various mechanical systems that lift and drop the warp threads. The sequence and control of this motion depend on the type of shedding mechanism installed in the weaving machine. The weft (crosswise yarn) is then inserted into the shed, after which the warp threads return to their original position and trap the weft to create a woven structure.

Fig. 1 Illustration of shed formation (Courtesy of Gov. of India Ministry of Textiles)

A synchronized combination of the shedding, picking, and beating motions results in the final fabric (Read in details here). Among these, shedding defines how versatile and complex your fabric design can be.

Why Shed Formation is Crucial in Weaving?

The importance of shed formation lies in its direct impact on the fabric’s structure, design potential, production speed, and quality.

A precise shedding mechanism ensures:

- Smooth and defect-free weaving

- Greater control over intricate fabric patterns

- Better productivity and less yarn breakage

- Freedom to innovate with unique designs and textures

At GAJERA IMPEX, the choice of shedding system is carefully matched with the fabric requirements to ensure maximum efficiency and consistent results.

Different Types of Shed Formation Mechanisms

Let’s look at the primary types of shed formation systems used in modern weaving machines and how they differ in function, design capability, and application.

Shaft (Heald Frame) Shedding

Shaft shedding is the most basic form, typically used for simple weaves like plain, twill, or satin. The warp threads are passed through heald wires mounted on frames (shafts), which are moved up and down mechanically. This system is economical, easy to maintain, and ideal for high-speed production of basic fabrics. However, it is limited in the number of design options.

Cam Shedding

Cam shedding uses a cam (a rotating disc) to move the shafts in a pre-set pattern. This method offers more flexibility than basic shaft shedding and allows the weaving of more complex structures like zigzags or diamonds. However, the cam system is limited by the number of shafts it can control and lacks flexibility for quick pattern changes.

Dobby Shedding

Dobby mechanisms are more advanced than cams. They can control up to 36 or more shafts, giving them the ability to weave complex patterns. Designs can be changed relatively easily using punched cards or electronic control. This system is highly suitable for producing decorative fabrics, apparel fabrics, and industrial textiles with mid-level design complexity.

Servo-Driven Shedding

A more recent innovation, servo-driven shedding systems use electric servo motors to individually control each shaft. This allows for precise movement, reduced mechanical wear, and faster pattern changeovers. It offers a high degree of automation and is ideal for modern, high-speed looms focused on efficiency and quality.

Jacquard Shedding

Jacquard shedding is the most sophisticated and design-flexible system. Each warp yarn is individually controlled using harness cords, allowing for extremely intricate and large-scale patterns — perfect for sarees, shawls, laces, upholstery, and fashionwear. Jacquard weaving enables endless design possibilities, but comes with higher costs and slower production speeds compared to basic systems.

Fig. 2 Jacquard shedding mechanism (Courtesy of Advanced Weaving Technology)

How Shed Formation Impacts Fabric Quality and Design?

The type of shed formation directly affects how accurately warp threads are lifted, how clean the shed is, and how smoothly the weft can pass through. A cleaner shed results in fewer yarn breaks, reduced machine downtime, and a better-quality surface.

For design, the more complex the shedding system, the more detailed and unique the fabric patterns can be. At GAJERA IMPEX, we use a combination of dobby and Jacquard looms alongside cam and shaft looms, enabling us to produce a wide spectrum of fabrics — from simple shirtings to richly patterned jacquard sarees and scarves.

Which Shedding System is Best for Which Fabric?

- Shaft Shedding: Ideal for basic weaves, greige fabric, bedsheets, plain shirtings, and twills.

- Cam Shedding: Best for medium-complexity fabrics like suitings and certain home textiles.

- Dobby Shedding: Suitable for kurtis, dress materials, ethnic fabrics, and mid-level patterning.

- Servo Drive: Great for high-speed production with design flexibility in technical or apparel fabrics.

- Jacquard Shedding: Essential for intricate patterns in sarees, lace fabrics, shawls, scarves, and premium home textiles.

Conclusion

At GAJERA IMPEX, our strength lies in our adaptability. By using the right combination of shaft, cam, dobby, servo drive, and Jacquard shedding systems, we’re able to deliver fabrics that meet the most demanding design, quality, and export standards.

Whether it’s a simple greige fabric or a heavily embellished jacquard saree, we make sure the weaving starts with precision shed formation, because that’s where every great fabric begins.

📩 Looking for a weaving partner who understands fabric from the yarn up?

Visit us at 👉 www.gajeraimpex.com or contact us for customised weaving solutions.