Jacquard fabrics are not just materials — they are masterpieces of weaving, where technology, design, and tradition come together. At GAJERA IMPEX, we take pride in weaving these rich, intricate textiles that stand as a symbol of excellence in the global fabric market. But how exactly is Jacquard fabric made, and why does it hold such a significant place in the textile industry? Let’s take a deeper look into the fascinating world of Jacquard weaving.

What is Jacquard Fabric?

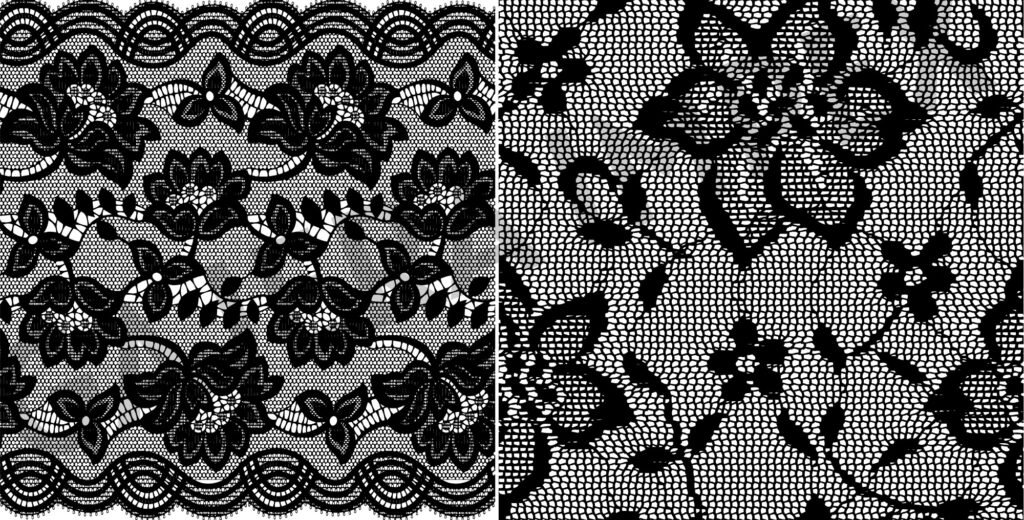

Jacquard fabric is a type of woven fabric that features complex patterns directly woven into the material, not printed or embroidered. These patterns can be floral, geometric, paisley, ethnic, or completely custom-designed. The name comes from the Jacquard loom, an innovative weaving mechanism developed by Joseph Marie Jacquard in 1804. This invention allowed individual control of each warp thread, enabling weavers to create detailed and repeatable patterns that were previously impossible.

How is Jacquard Fabric Woven?

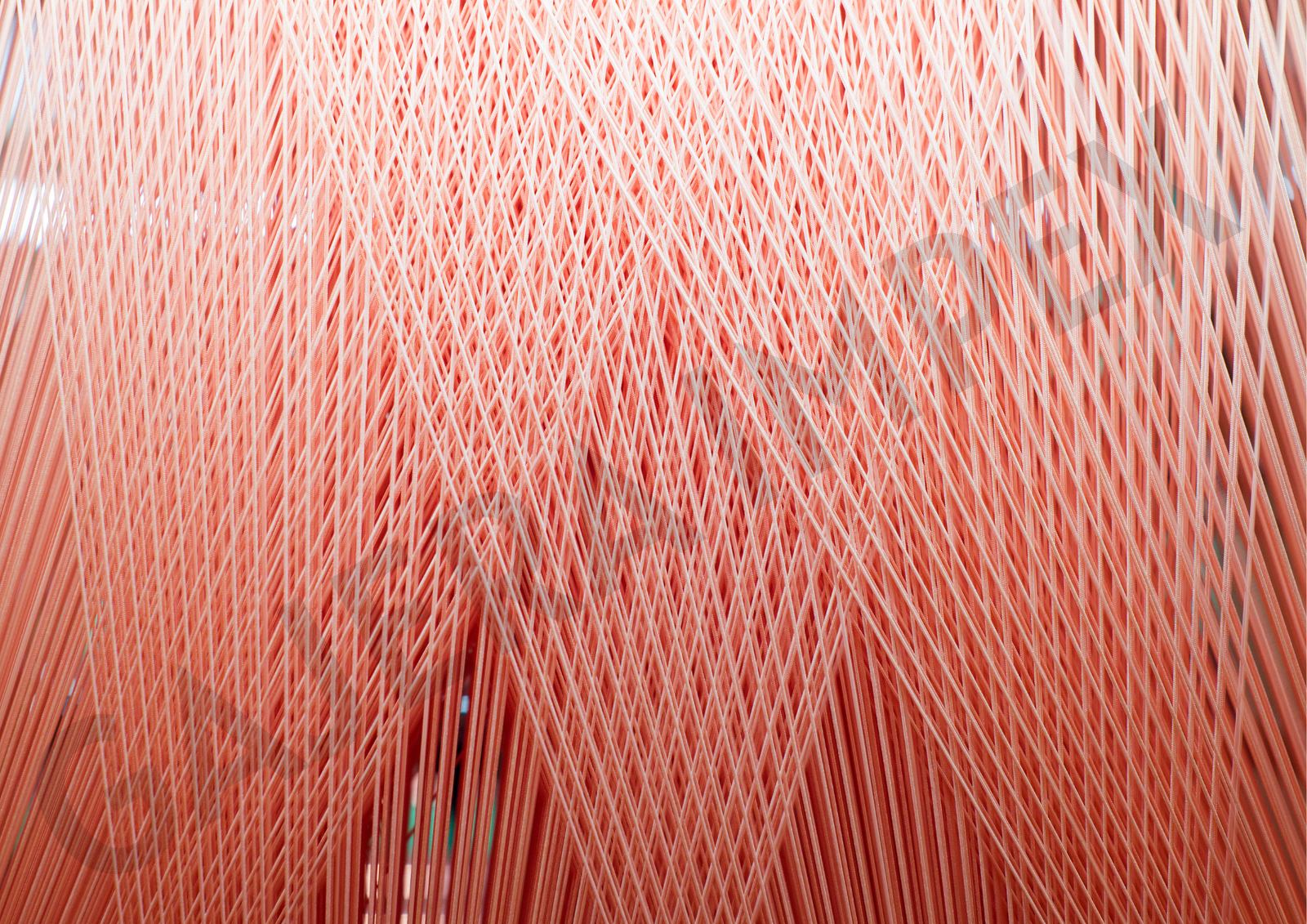

The process begins with high-quality yarns—often cotton, viscose, polyester, or blended fibers—which are loaded onto the loom. Unlike plain or twill weaves, Jacquard weaving requires a Jacquard attachment, which is mounted atop a loom. This attachment operates via a complex system of hooks, harness cords, and either punched cards or electronic instructions, each one dictating which individual threads should be lifted or lowered.

As the loom operates, the Jacquard mechanism allows each warp yarn to move independently, which is what makes intricate patterns and multi-dimensional textures possible. The process is more labour-intensive than regular weaving, but the results are visually and structurally superior.

Types of Jacquard Fabrics

Any type of fabric woven with a Jacquard loom is considered to be jacquard fabric. There are quite a few different subtypes of jacquard fabric, and we’ll cover a few of the most common used jacquard fabric types.

Jacquard fabrics come in many forms depending on their use, weight, and material. Some common types include Brocade, which has a raised pattern often made with metallic threads; Damask, known for its reversible designs with subtle elegance; Matelassé, a quilted-looking fabric; and Tapestry, used for heavy decorative applications. In apparel, lighter Jacquard fabrics are used for traditional sarees, kurtis, dresses, scarves, and ethnic wear, while thicker varieties find their place in home textiles like upholstery and curtains.

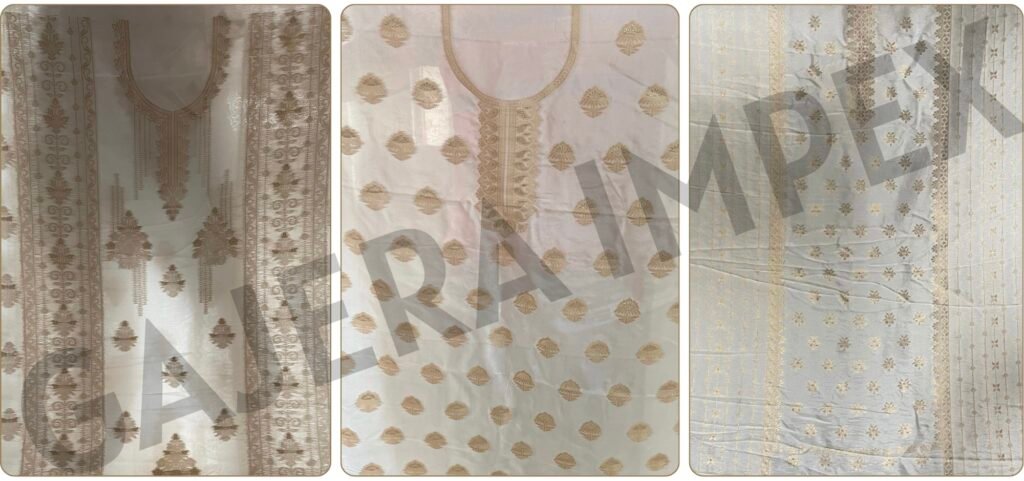

At GAJERA IMPEX, we specialise in creating customised Jacquard fabrics tailored for both the fashion and home textile industries, meeting diverse global demands. We are producing jacquard fabrics by using cotton, polyester, viscose, nylon and all other kinds of high-quality yarns by considering customer requirements.

The Importance of Jacquard Fabric in the Textile Industry

Jacquard weaving is a cornerstone of value-added textile production. Its ability to embed design directly into the fabric increases the product’s longevity, visual appeal, and luxury factor. It enables the creation of high-end fashion textiles, premium ethnic wear, and durable home furnishings, all of which command a higher market value. For designers and manufacturers, Jacquard offers unmatched creative freedom.

Jacquard vs. Plain Grey Fabrics

The difference between Jacquard and regular grey fabrics lies in both complexity and purpose. Grey fabrics, often produced on shaft or cam looms, are typically simple plain, twill, or satin weaves that serve as a base material for further processing like dyeing or printing. They are functional and versatile, but lack decorative elements. Jacquard, on the other hand, is design-oriented, often requiring no additional surface decoration, and offers a complete product in itself with texture, pattern, and aesthetics already built in.

What Makes Jacquard Weaving Unique?

To produce Jacquard fabrics, a weaving unit needs more advanced infrastructure. A standard loom setup must be upgraded with a Jacquard mechanism—either mechanical or electronic—depending on production scale and design complexity. Additional elements include pattern software, data feeding units, and highly skilled technicians. This setup differentiates Jacquard weaving from other systems like shaft, cam, or dobby, where pattern complexity is limited due to grouped yarn movements.

Jacquard vs. Dobby, Shaft, and Cam

The primary difference between Jacquard and dobby or shaft-based weaving lies in the independent control over warp threads. In shaft, cam, or dobby mechanisms, the warp threads are controlled in grouped sets, restricting the complexity of the patterns. Dobby looms can handle more intricate designs than cam or shaft but still fall short compared to Jacquard in terms of detailing. Jacquard looms allow each warp thread to be manipulated independently, giving designers infinite freedom and enabling highly intricate and large-scale designs.

—

At GAJERA IMPEX, weaving Jacquard fabrics has been our Unique Selling Proposition (USP) for decades. With years of expertise and innovation in the textile industry, we have proudly been manufacturing and exporting premium Jacquard fabrics across domestic and global markets. What sets us apart is our in-house Jacquard design house, where creativity meets technology. This allows us to not only produce intricate, high-quality patterns but also to offer customized Jacquard fabric solutions tailored to specific customer requirements. Whether it’s traditional elegance or modern sophistication, our team ensures every weave reflects precision, passion, and purpose.

For inquiries or custom Jacquard developments, visit our website: www.gajeraimpex.com or contact us at sales@gajeraimpex.com