In the world of textiles, everything begins with the smallest structural unit: the fiber. Whether it’s a soft cotton saree or a durable polyester curtain, the fabric’s quality, texture, strength, and appearance are all rooted in the type of fiber or filament used in its creation. At GAJERA IMPEX, a global manufacturer and exporter of textile fabrics, it’s essential for us to understand and utilize the fundamental differences between fibers and filaments to deliver fabrics that meet specific performance and comfort expectations.

What Is a Fiber in Textiles?

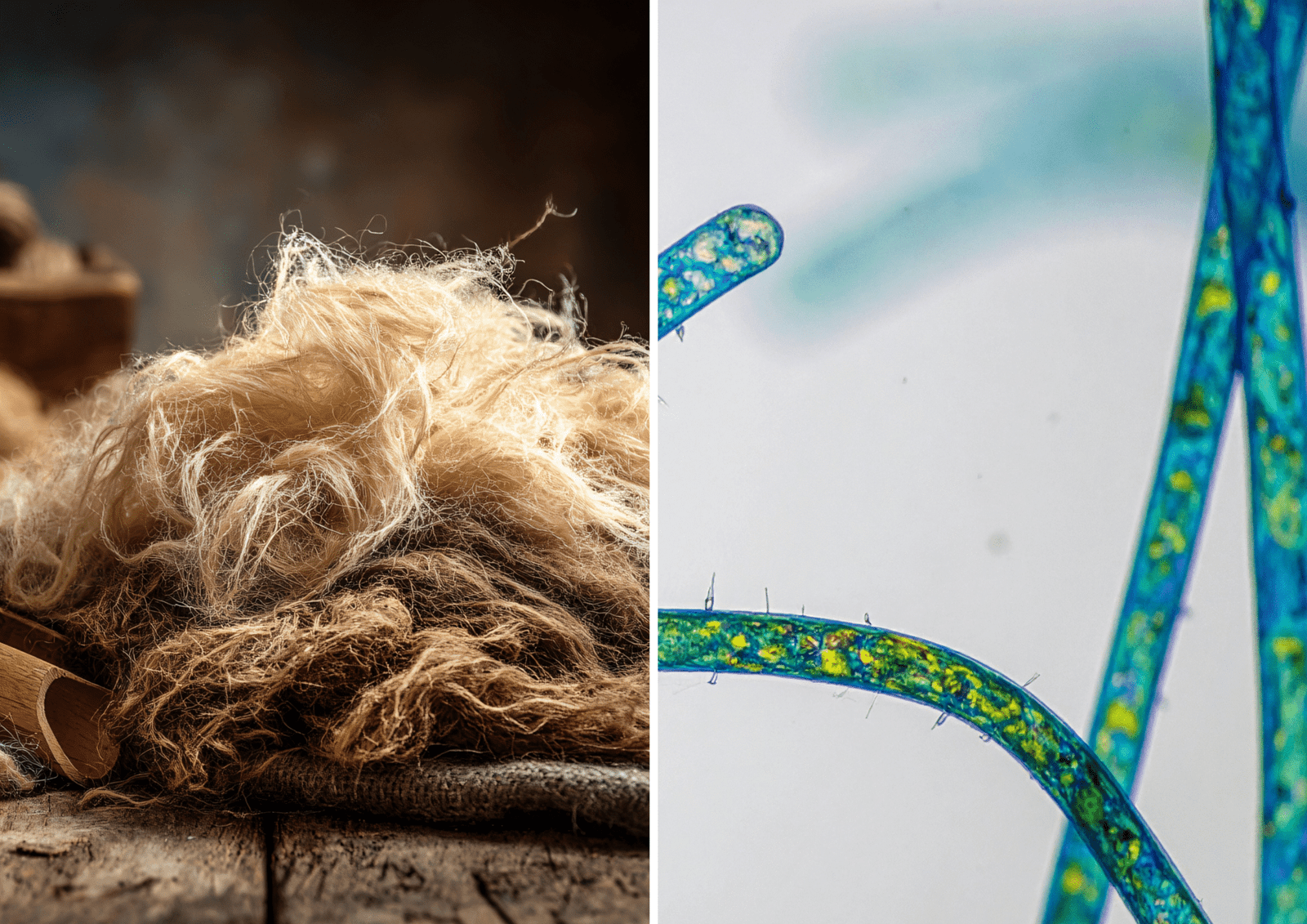

A fiber is a small, hair-like structure that is the basic raw material for making yarns and fabrics. It is defined by its short length and its ability to be spun into yarns. Most natural materials like cotton, wool, jute, and flax are considered fibers because they exist in short, discrete lengths, also known as staple lengths. These fibers must be twisted or spun together to form continuous yarns, which are then woven or knitted into fabric.

Scientifically, fibers have a length-to-diameter ratio that allows them to be flexible, strong, and processable into textiles. The length of a staple fiber usually varies, but in general, it can range from a few millimeters to several centimeters, depending on the source and processing.

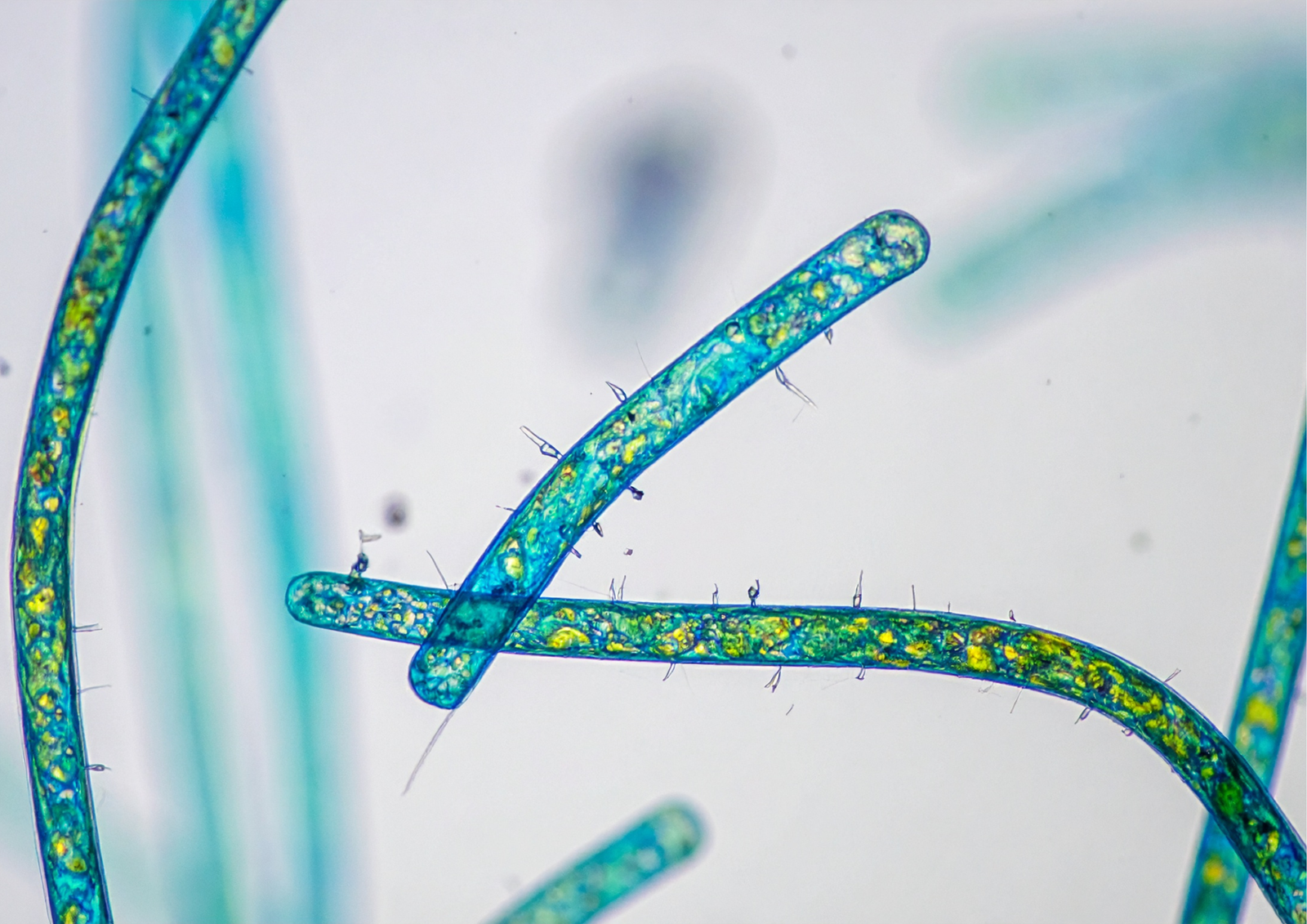

What Is a Filament in Textiles?

In contrast to fibers, a filament is a continuous or an infinite length of fiber. It is significantly longer than a staple fiber and can extend to hundreds or even thousands of meters without breakage. Filaments are typically synthetic in origin, such as polyester, nylon, and rayon, but there is one natural filament fiber: silk. Silk filaments are produced by silkworms and can reach unbroken lengths of up to 1,000 meters, making silk the only natural continuous filament.

Filaments are generally smoother, shinier, and stronger than staple fibers due to their length and uniformity. They are often used in applications where strength and a sleek appearance are important, such as in technical textiles, athletic wear, and luxurious garments.

How to Identify Whether It’s a Fiber or Filament?

Identifying whether a textile material is a fiber or a filament depends primarily on its fiber length and structure. If the material consists of short pieces that need to be spun together to create a yarn, it is considered a fiber or staple fiber. On the other hand, if the material is already in a long, continuous form, it is known as a filament.

In practice, staple fibers have a fuzzy, textured appearance in yarns, while filaments give a smooth and lustrous finish. Filament yarns can also be monofilament (single strand) or multifilament (several strands twisted together), depending on the intended use.

What Is Staple Fiber and What Is Its Length?

A staple fiber is a fiber of short, limited length. Natural fibers such as cotton and wool are classic examples of staple fibers. Their length can vary based on the source — for example, cotton fibers typically range between 0.5 to 2 inches (12 to 50 mm), while wool fibers can range from 1.5 to 15 inches (40 to 380 mm), depending on the breed of sheep.

Even synthetic materials can be cut into staple lengths to mimic the properties of natural fibers. For example, polyester staple fiber (PSF) is a manufactured fiber that is chopped/cut into specific lengths to blend with cotton and other natural fibers. These synthetic staple fibers are used in applications where the user wants the feel of natural fiber with the strength of synthetic fiber.

Can a Filament Become a Staple Fiber?

Yes, a filament can be converted into a staple fiber through a process called cutting or chopping. This is commonly done in the textile industry to produce synthetic fibers in staple form, so they can be blended with natural fibers. For example, long polyester filaments can be chopped into short lengths to match the staple length of cotton, allowing for smooth blending and improved fabric characteristics.

However, the reverse is not possible. Staple fibers cannot be converted into filaments, as their natural form is already limited in length.

Why Does It Matter? How It Impacts Fabric Quality?

The choice between staple fiber and filament has a profound impact on the feel, appearance, and performance of fabric. Fabrics made from staple fibers tend to be softer, warmer, and more breathable, which makes them ideal for apparel like kurtis, sarees, and traditional garments — specialties of GAJERA IMPEX. On the other hand, fabrics made from filaments tend to be sleek, smooth, and shiny, making them perfect for linings, formal wear, sportswear, and technical applications.

Moreover, filament yarns tend to pill less and have higher strength and elasticity, while staple yarns provide better insulation and absorbency, qualities valued in home textiles and comfort clothing.

Conclusion

Understanding the difference between fibers and filaments is fundamental to fabric manufacturing. At GAJERA IMPEX, we make informed decisions about fiber and filament selection based on the desired fabric characteristics, end-user requirements, and global market trends. Whether you’re sourcing for breathable cotton fabrics or high-strength polyester blends, we ensure that every material used meets the highest standards in quality, durability, and sustainability.

For custom fabric solutions and export inquiries, connect with our team or explore our offerings at www.gajeraimpex.com or directly send an Email at sales@gajeraimpex.com for any inquiries or information. Experience the science of textiles—woven with precision, delivered with excellence.