In the textile world, precision and clarity are crucial at every stage of production. Whether it’s for spinning, weaving, or quality control, one essential aspect that ensures consistency is the measurement and classification of yarns and fibers. This is where textile units and yarn numbering systems come into play. At GAJERA IMPEX, as a leading manufacturer and exporter of high-quality fabrics, we pay careful attention to these units to ensure we deliver uniform, dependable textile products to clients across the globe.

What is a Textile Unit and Why Is It Important?

A textile unit refers to a standardized measurement system used to describe various physical properties of yarns and fibers, especially thickness, fineness, and length-to-weight ratios. Understanding these units helps manufacturers, buyers, and designers interpret how thick, fine, strong, or soft a yarn or fabric will be. It also plays a crucial role during spinning, weaving, and final garment processing because fabric density, appearance, and durability are all directly influenced by yarn specifications.

Types of Yarn Numbering Systems in Textiles

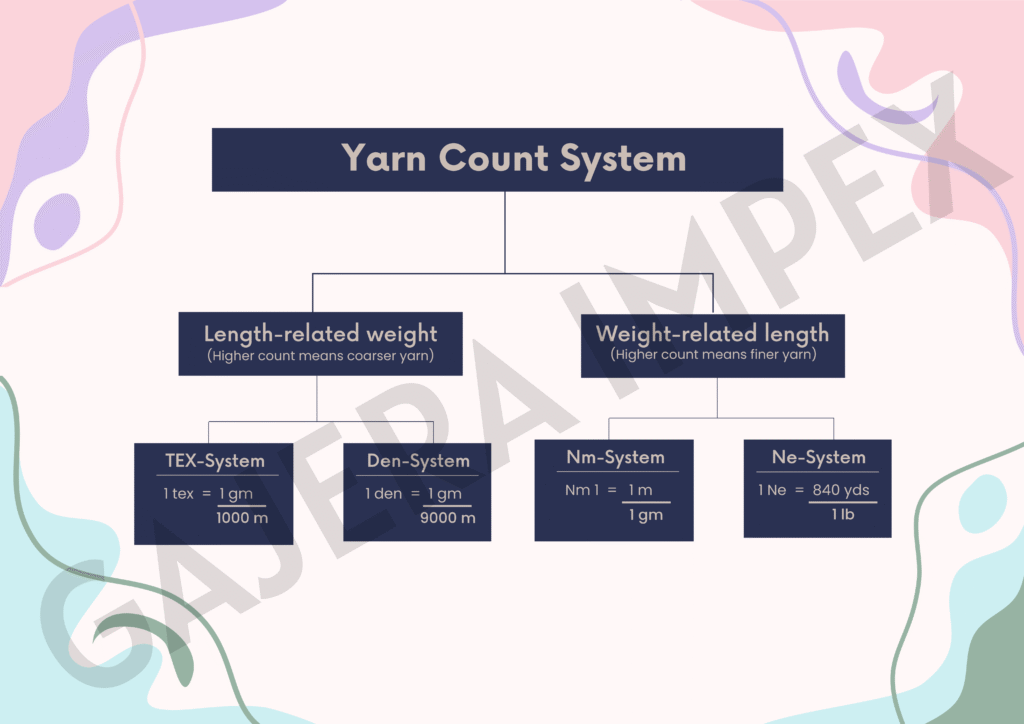

Yarn numbering systems can be broadly divided into two categories: direct systems and indirect systems. These systems define how we express yarn fineness or thickness. Each system is based either on the mass per unit length or the length per unit mass of yarn.

TEX System

The TEX system is a direct system, meaning the higher the number, the thicker the yarn. It defines yarn size as the weight in grams of 1,000 meters of yarn. For example, a 30 TEX yarn weighs 30 grams per 1,000 meters. This system is widely used internationally and provides a straightforward and standardized method to compare yarns.

TEX = (Weight in grams / Length in meters) × 1000

This system is useful in technical and industrial textiles where consistent sizing and durability are key factors.

Denier (Den) System

The Denier system is another direct system and is commonly used for filament yarns such as polyester, nylon, and silk. It measures the weight in grams of 9,000 meters of yarn. A lower denier indicates a finer yarn, while a higher denier indicates a thicker, stronger yarn. For example, sheer hosiery may use 10 denier yarn, while heavier outerwear might use 100 or more.

Denier = (Weight in grams / Length in meters) × 9000

Silk is an example of a natural filament that is often measured in denier. In synthetic fibers, denier is critical in applications such as sportswear, parachutes, or upholstery fabrics.

Nm-System (Number Metric)

The Nm system, or Number Metric, is an indirect system where yarn fineness is expressed as the number of meters of yarn per gram. The higher the Nm number, the finer the yarn. For example, an Nm 30 yarn means 30 meters of the yarn weighs one gram.

This system is commonly used in Europe, especially for wool and wool-blended yarns.

Ne-System (Number English)

The Ne system, also called Number English, is another indirect system and defines yarn count as the number of 840-yard lengths per pound of yarn. A Ne 20 yarn means that 20 hanks of 840 yards weigh one pound. Like the Nm system, a higher Ne number indicates a finer yarn.

This system is widely used in cotton spinning and is common in English-speaking countries.

Why Are These Systems Important in Spinning and Weaving?

Selecting the right yarn count and type is critical for determining fabric density, texture, strength, drape, and overall quality. During the spinning process, these systems guide the blending of fibers and adjustment of machines. In weaving, they affect warp and weft tension, loom settings, and ultimately the appearance and feel of the final fabric.

Using standardized units ensures that the entire supply chain—from raw material processors to garment manufacturers—remains in sync, especially when producing at a global scale.

What is Yarn Designation?

Yarn designation refers to the complete identification of a yarn in terms of its fiber material, yarn count or size, number of filaments (for filament yarns), and plying (number of yarns twisted together). Proper yarn designation helps ensure the right yarn is used for the right application.

Here’s how to read a full yarn designation:

Example: PES 30f12/2

PES: Polyester – Fiber material

30: Yarn count in Den (direct system, meaning 30 grams per 9000 meters)

f12: Number of filaments in the yarn (f = filaments)

2: Plying, here two yarns twisted together to form one stronger, thicker yarn

This designation tells us that the yarn is made from polyester, has medium thickness, contains 12 individual filaments, and is composed of two strands twisted together for added strength and structure.

Conclusion

Understanding textile units and yarn numbering systems is foundational to producing high-quality fabrics. Whether it’s TEX, Denier, Nm, or Ne, each system provides a unique lens through which yarn fineness and fabric performance can be assessed. At GAJERA IMPEX, we take pride in using globally recognized textile units to guide our production process, ensuring each fabric meets the specific needs of our customers. From weaving fine shirting to creating durable home textiles, the correct understanding of yarn properties helps us deliver excellence in every meter we export.

Explore more about our expertise and fabric offerings at www.gajeraimpex.com, where innovation is woven into every thread.